KNOWLEDGE

Latest Article

CATEGORY

High-Pressure Pump Knowledge

22.May.2024

Introduction of Four Main Index of High Pressure Pump Specification

When selecting suitable high-pressure pump equipment, there are many specification indicators to consider. This article will focus on introducing the four key specification indicators of high-pressure pumps: flow rate, pressure, speed, and horsepower. However, before delving into these high-pressure pump specification indicators, let's first review the basic concepts of pumps.

This article will be introducing the four key index of high-pressure pumps in detail: flow rate, pressure, speed, and horsepower. In the meantime, readers are able to understand the importance and the application when selecting high-pressure pump equipment.

In conclusion, understanding the importance of indicators such as flow rate, pressure, rotational speed, and horsepower of high-pressure pumps is crucial for selecting the appropriate equipment. Choosing the right specifications of high-pressure pumps based on different applications can enhance work efficiency, reduce costs, and ensure the reliable operation of the equipment. If you have any further questions or needs, please feel free to contact us. We are dedicated to providing you with professional solutions and services.

What is a pump?

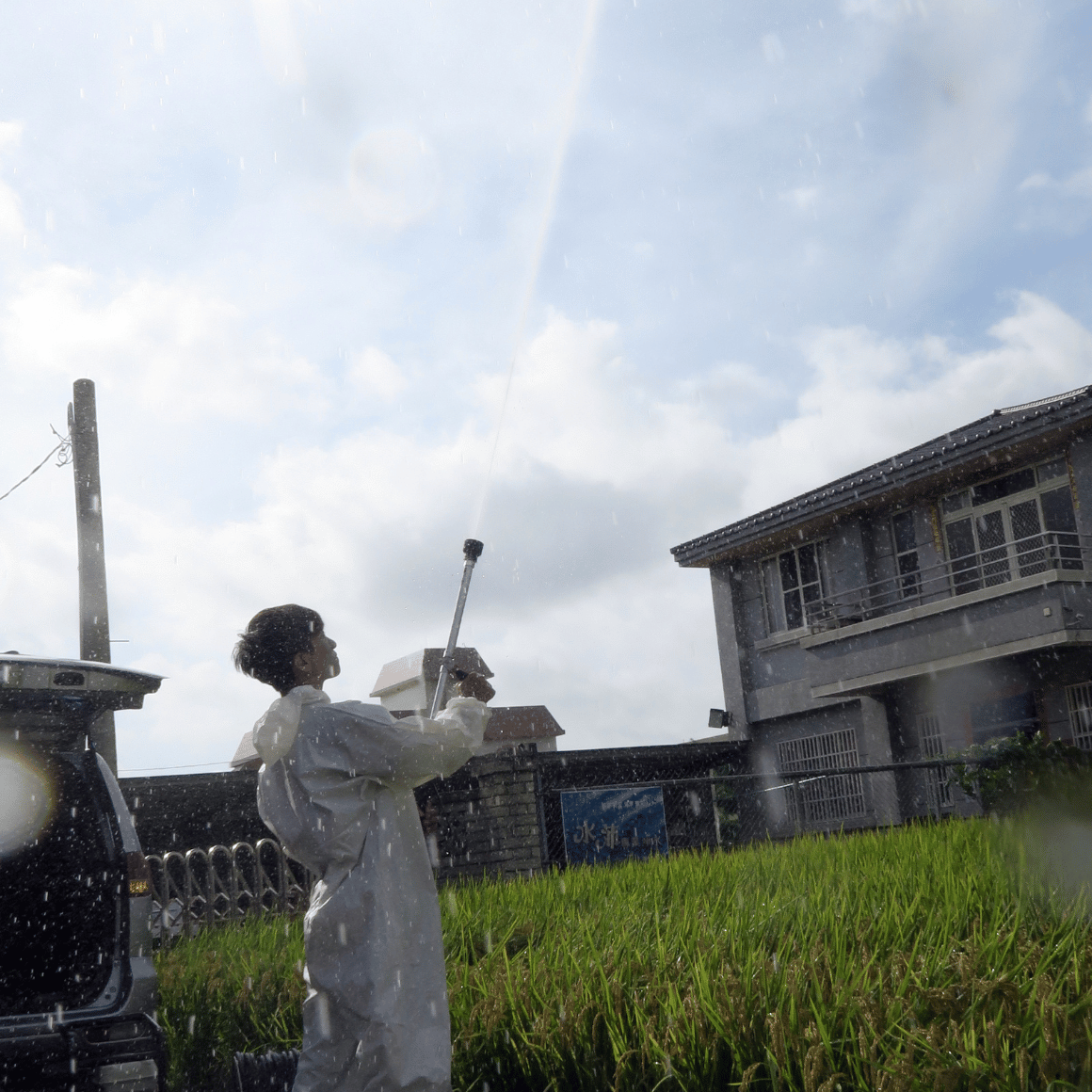

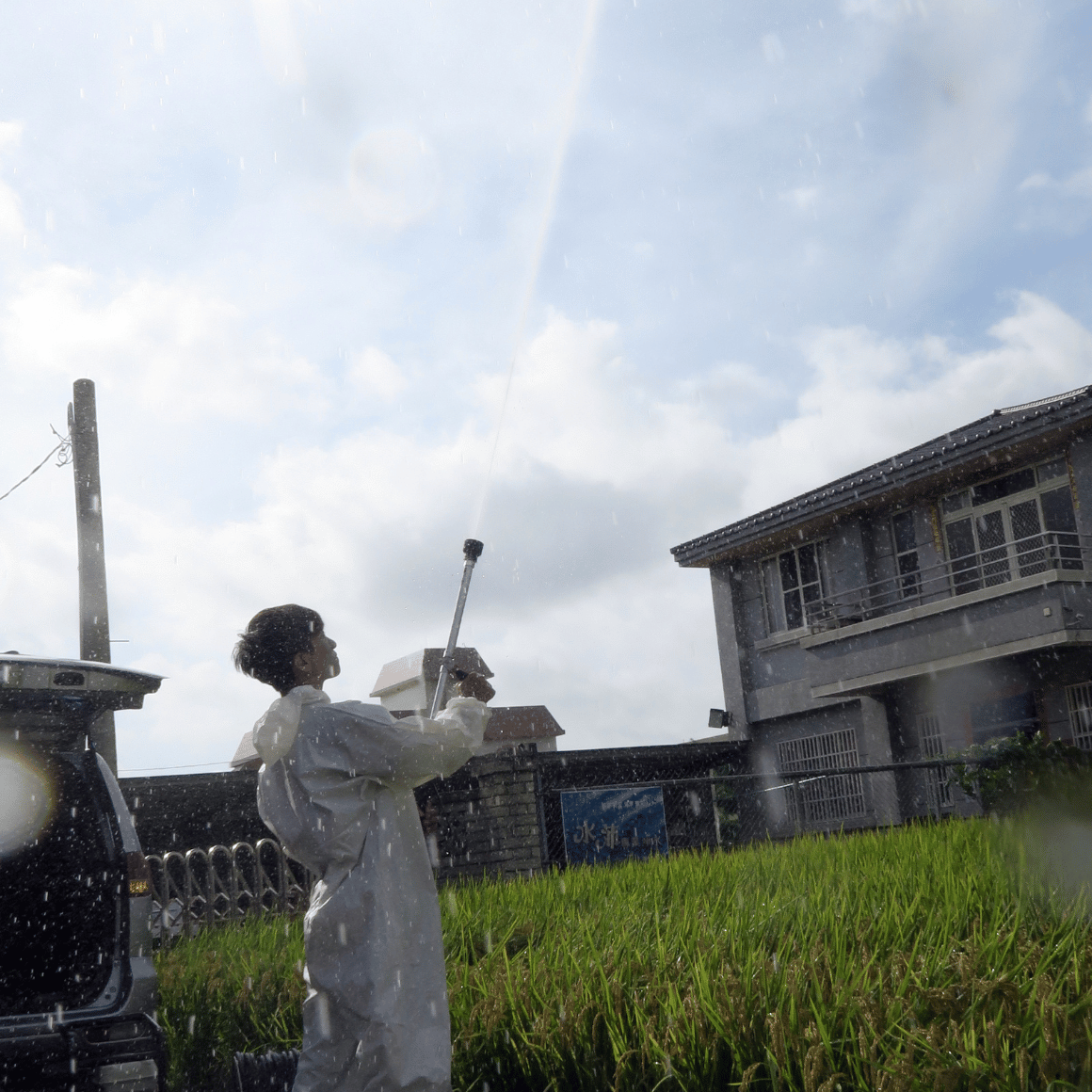

A pump is a machine used for transferring liquids. It can draw liquid from one place and move it to another and continue to maintain the flow of the fluid. Pumps typically consist of a driving mechanism (such as an electric motor or diesel engine), transport components (such as pistons), and a piping system. Pumps have a wide range of applications, including but not limited to agricultural irrigation, livestock applications, industrial electromechanical integration, high-pressure cleaning systems, and misting systems.This article will be introducing the four key index of high-pressure pumps in detail: flow rate, pressure, speed, and horsepower. In the meantime, readers are able to understand the importance and the application when selecting high-pressure pump equipment.

Flow Rates

Flow rate refers to the volume of liquid that a high-pressure pump delivers per unit of time. It can be expressed in liters per minute (L/min), with other common units including cubic meters per hour (m³/h), gallons per minute (GPM), and cubic feet per minute (CFM). In certain application scenarios, such as sprayers and misting systems, high-pressure pump needs to achieve to a specific standard flow rate to ensure that the sprayed liquid can evenly covers the target surface and achieves the desired effect. The required flow rate of a high-pressure pump depends on the application and the design of the piping system.

Pressure

Pressure refers to the force exerted by the high-pressure pump to the liquid, typically measured in bars (bar) or pounds per square inch (psi), with one bar being approximately equal to kilograms per square centimeter (kg/cm²). For applications such as high-pressure washers, a pump with high pressure is required to ensure effective surface cleaning. The pressure of a high-pressure pump is closely related to its flow rate, and together, they determine the pump's delivery capacity.

Rotational Speed (RPM)

Rotational speed of the high-pressure pump is usually measured in revolutions per minute (RPM). The speed of a high-pressure pump directly affects its delivery efficiency and lifespan. Generally, pumps with higher speeds can provide greater flow rates and pressures, but they also increase energy consumption and noise levels. Therefore, when selecting a high-pressure pump, it is important to balance speed with performance.Horsepower

Horsepower (HP) refers to the power of the high-pressure pump's driving mechanism. The horsepower of the pump can affect the delivery capacity and efficiency. When selecting the horsepower of high-pressure pump, higher horsepower is not always better. Excessive horsepower can lead to energy waste and the increases unnecessary cost. On the other hand, appropriate horsepower ensures high-pressure pump operates at optimal efficiency while maintaining stable performance. Therefore, while considering horsepower of the pump, it is essential to consider factors such as the required flow rate, pressure, and speed to ensure that the selected horsepower adequately meets the actual application needs.The relationships between specifications:

Different specifications of high-pressure pumps are interrelated. For instance, flow rate and pressure often affect each other (similar to the experience of reducing flow by pinching a hose's nozzle, which increases pressure). In some cases, increasing flow rate may decrease pressure, and vice versa. There's also a correlation between the pump's rotational speed and horsepower. Higher rotational speeds may require a more powerful motor to maintain the desired performance level.In conclusion, understanding the importance of indicators such as flow rate, pressure, rotational speed, and horsepower of high-pressure pumps is crucial for selecting the appropriate equipment. Choosing the right specifications of high-pressure pumps based on different applications can enhance work efficiency, reduce costs, and ensure the reliable operation of the equipment. If you have any further questions or needs, please feel free to contact us. We are dedicated to providing you with professional solutions and services.