PRODUCT

Product

Description

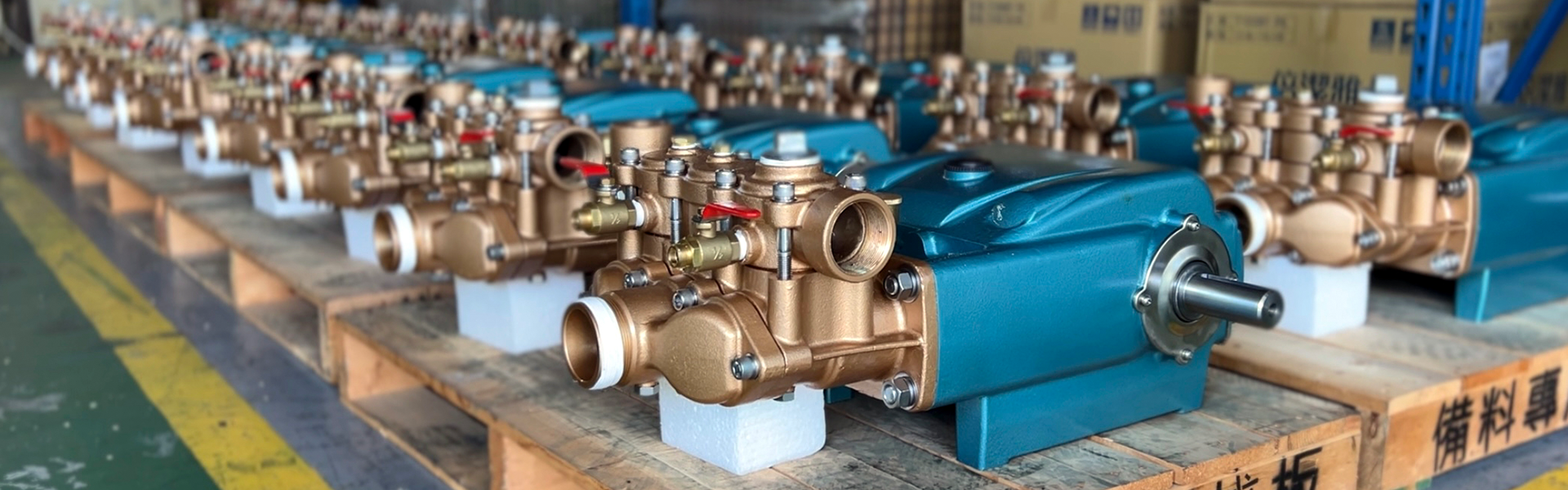

MDC series is a low RPM professional pump designed for long consecutive operation and medium to high flow rate application. It is built of SS316 manifold to resist corrosion, and constructed with enhanced components to withstand 24-7 consecutive operation.

This series has very good long consecutive working ability and low noise performance compares to other high pressure pumps in the market. This is a result of our insistence in high precision and high quality components. For example, the high pressure packing is made of memory high molecular engineering plastic and low pressure packing is made of NBR to enhance endurance. Others like precision ceramic plungers, chrome molybdenum alloy steel crankshaft, cast aluminum alloys crankcase, and forged steel connecting rods with lubricated sleeve, etc. are the reasons of excellent performance and long life of our high pressure pumps.

This series has very good long consecutive working ability and low noise performance compares to other high pressure pumps in the market. This is a result of our insistence in high precision and high quality components. For example, the high pressure packing is made of memory high molecular engineering plastic and low pressure packing is made of NBR to enhance endurance. Others like precision ceramic plungers, chrome molybdenum alloy steel crankshaft, cast aluminum alloys crankcase, and forged steel connecting rods with lubricated sleeve, etc. are the reasons of excellent performance and long life of our high pressure pumps.

Application

-

Cleaning and Cooling in machining process

In the process of machining, using hydraulic to apply coolant to cutting tools or grinders will not only wash away the cutting scraps but also cool down the working temperature to protect cutting tools and grinders. High pressure fluid can also be used to wash finished products and clean up equipment after use.

With the use of spray nozzles at correct lineup, positioning, and angles, plus a PLC-based control system, the high-pressure fluid can also be used throughout the machining process to wash away lubricate, and grinding or cutting additives. -

Deburring

During the process of machining, casting, and forging, etc., strong hydraulic fluid can be used to remove the burr on cut edge or joint lines on the produced objects. -

Debarking

A high pressure pump can be used to apply high pressure fluid onto trees to remove barks or coating on woods. No chemical or heat for softening are required and no peeling tool is needed.

-

Pipe Testing

A high pressure pump is used to fill hydraulic fluid inside of a pipeline. The pressure is built to a testing point by filling up fluid, and once the pressure reaches the testing point, inlet will be closed to monitor the pressure change inside of the pipeline. If pressure is found gradually dropped, there is at least one flaw in the pipeline. This test is mostly conducted to guarantee the perfection of buried high pressure pipelines. -

Wet Sand Blast

When the high-pressure fluid goes through a designed nozzle, it creates a vacuum and draw the sand from a container to go along, and becoming a wet sand blast. This wet sand blast is ideal to work on objects in complicate forms, without concern of making damage to the object and flying sand particles, to remove the burr and clean up unwanted adherents on the objects. -

Condenser Tube Cleaning

Heat exchanger is a system to transfer the heatenergy between hot fluid and cold fluid, to meet the demand in manufacturing orenvironment. It is used for both heat exchange and heat transfer in industrialapplications, commonly seen in chemical plants, refrigeration, and airconditioning, etc. But when calcium carbonate deposit starts to be built upinside the condenser tubes, the efficiency of heat exchanger will be severelyreduced. A popular way to clean up these deposit is by using high-pressurefluid pushed through special designed spray gun and nozzle to wash away suchdeposit and restore the system efficiency back to origin.

-

Heavy Equipment Wash

Construction equipment, such as digging machinery, shoveling and transporting machinery, compressing machinery, are all heavy equipment. After working a long period of time in environments full of sticky dirt and dust, it requires heavy duty high pressure washers to peel off and wash away those piled up sticky objects. -

Tank & Tote Cleaning

Barrels, tanks, Buckets, or large bags are often used for solid or liquid storage in chemical or food industries. During frequent and continuous long-time use, the leftover of previous object may contaminate next object if the container is not cleaned well in transitions. A popular way to clean these containers is by a high pressure washing facility along with special designed nozzles, ex. 360 degree rotating nozzle, to thoroughly and effectively wash and clean these containers to ensure cleanness for next use. -

Moss and Mold Removing

On the walls of buildings, floors, and wooden boards, moss and mold often grow in a shadowed and humid environment. These moss and mold not only pollute the environment but also bring disease to human body. A high pressure washer is a great tool to remove and wash away these moss and mold efficiently in a large area without making any damage to the surfaces.

-

Sewage Cleaning

The large scale of urban underground sewage system used for water draining, food leftover, human waste, and waste fluid could be clogged from years of heavy works. As most sewage system does not have large pipes to accept large cleaning device, the best way is to use high flow rate of high pressure pump and lance nozzle to unclog the blockage and to flush the blockage to designated point for removal. -

Oil Paint Removing

Removing high adherent paint from various equipment and buildings during servicing, maintaining, repairing, and refurbishing are often proved challenging. Using chemical solvent could be harmful to human health and environment, using sand blast is good only for small area, and using scraping tools is time consuming. Nowadays the popular way is to use high pressure or ultra-high pressure spray in straight jet or fan spray to remove the paint, which is more environment friendly and no harm to human health.

ACCESSORIES

Specification

|

MODELS

|

Flow Rate

(L/min)

|

Rated Pressure

(kg/cm2)

|

rpm

|

HP

|

Weight

(kg)

|

| MDC-60/90 | 61.0 | 90 | 800 | 15.0 | 29.5 |

| MDC-45/120 | 48.2 | 120 | |||

| MDC-35/160 | 36.9 | 160 |

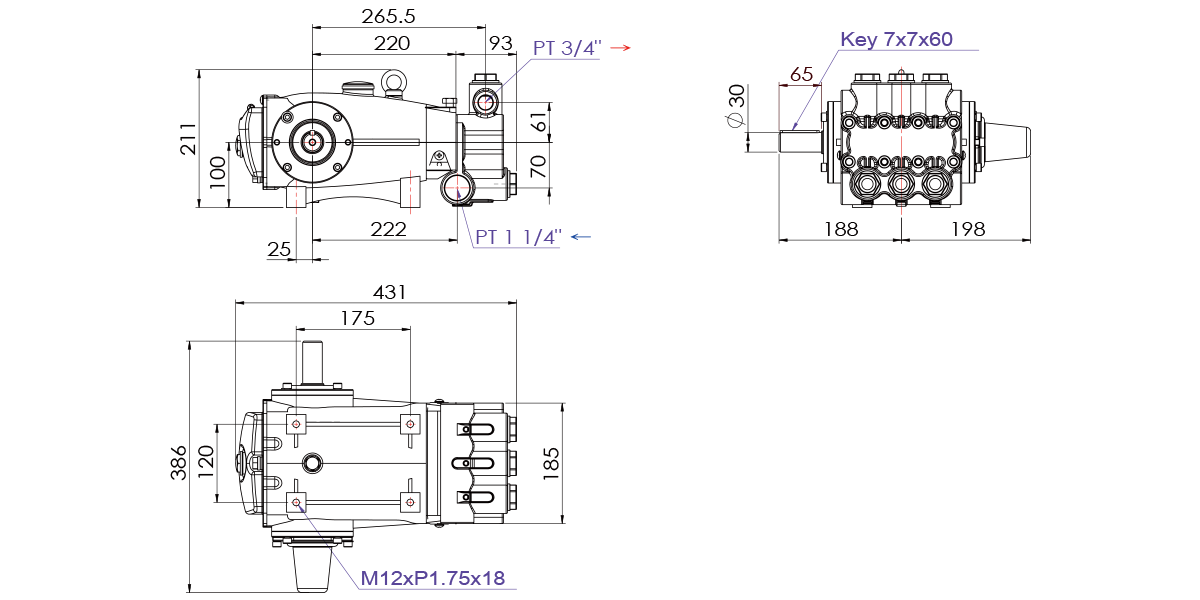

Dimention