PRODUCT

Product

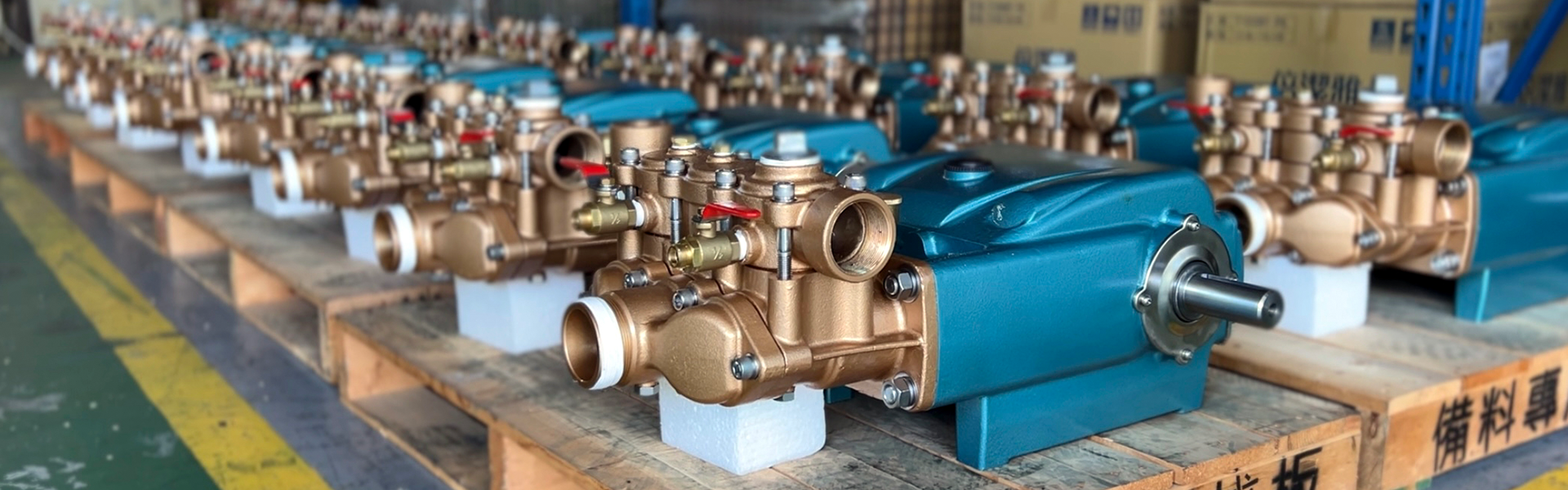

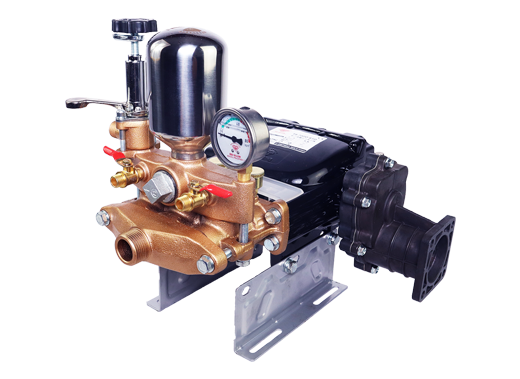

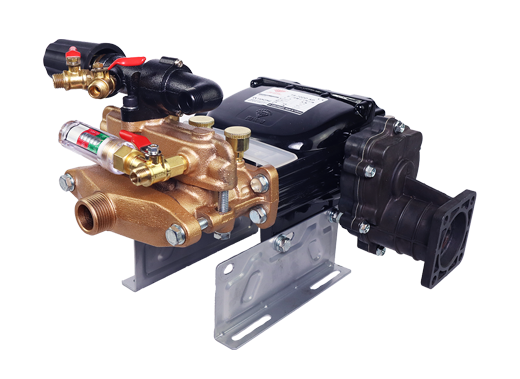

HTP Power Sprayer (Direct Drive)

History of Derect-drive HTP power sprayer

The surrounding environment of a working power sprayer has always been relatively harsh. Considering the corrosiveness of the spraying chemical and the contamination of the liquid solution, and the sustainable RPM of the water seal system is limited by material technology, the operating speed of the power sprayer is generally between 600 and 1200 RPM. Moreover, a certain lubricating grease is needed to add periodically to prevent premature leakage caused by excessive wear.

Compared to the high RPM of motors or engines, which typically exceed 1500 RPM, conventional sprayers usually reduce their operating speeds by using different ratios of pulleys. However, this approach usually lead to wear and tear between belts and pulleys, as well as potential injury caused by accidental entanglement by belts and pulleys. Not to mention the overall size of the sprayer unit is always enlarged and making it challenging to move the whole unit.

With the progression of gear technology, Tanong has successfully developed a 1:4 ratio gearbox and implemented it to our TS series power sprayers. This design significantly reduces the size of sprayer unit, eliminates the risk of belt entanglement injury, and gives way to use of less expensive high-speed engines or two-pole motors by increased efficiency of power transmission. Leading to a substantial reduction in operating costs of consumables and energy consumption.