PRODUCT

Product

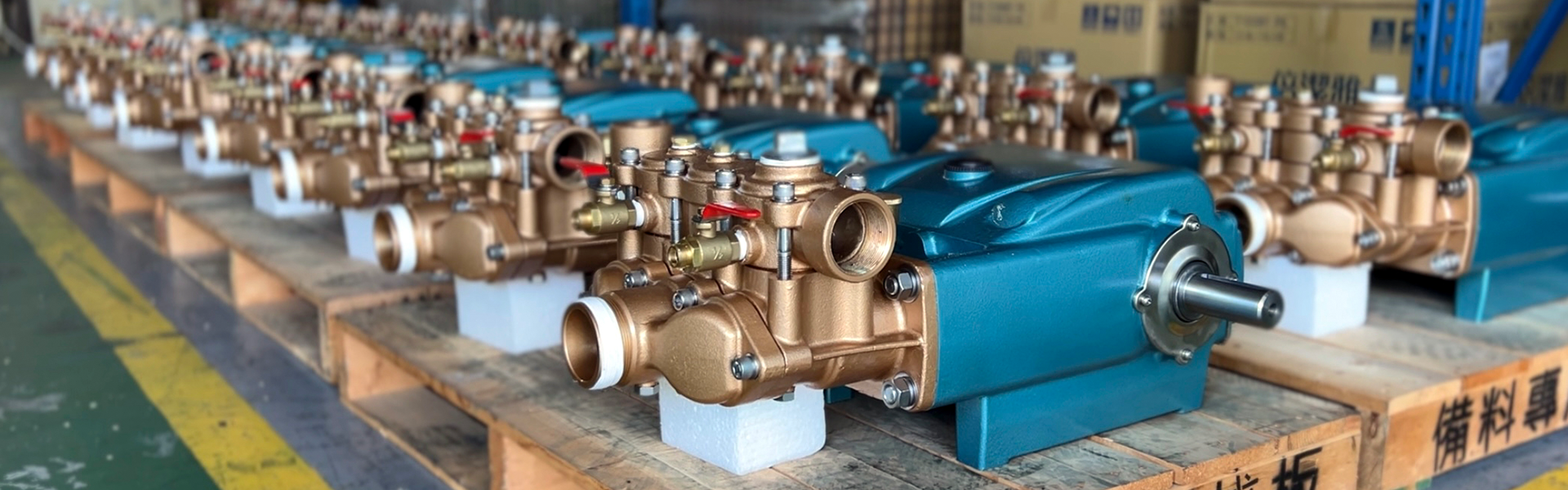

Triplex Pumps/Plunger Pumps

How Triplex Pumps/Plunger Pumps Work

A Triplex Pumps/Plunger Pumps is a device that moves fluid by mechanical action from one place to another through hydraulic energy. Such pumps include plunger pump, piston pump, gear pump, and multistage centrifugal pump, etc. Our high pressure pumps are mainly the type of crankshaft driven reciprocating positive-displacement plunger pumps, along with few piston pumps and radial axial block driven pumps. Our pumps capability is in range of following:

- Working pressure: 0 ~ < 300 bar

- Flowrate: 250 ml/min ~ 270 L/min

- Required HP: ¼ HP ~ 60 HP

Application Of Triplex Pumps/Plunger Pumps

High pressure triplex Pumps generate high fluid pressure through a serial mechanical action to transfer the energy from power source to plunger or piston and to the fluid. Combine the use of different types and designed nozzles, the high fluid pressure can be used for different applications as following:

Misting (Cooling, humidification, dust suppression, disinfection, fire control, disease prevention, landscape special effect, etc.)

Cleaning (vehicle cleaning, environment cleaning, industrial cleaning, etc.)

Waterjet cutting

Fluid delivery (High pressure boiler Feed water, Oil well Feed water, etc.)

Our high pressure pump systems are built of various devices, electric components, and logic control units. Different frameworks are designed for different customer’s needs. The whole systems include, not limited to, high pressure pump, driving power, driving mechanism, pressure control unit, logic control unit, tubing design, electric wirings, housing case, and safety protection, etc.

Specifications Of Triplex Pumps/Plunger Pumps

Our high pressure pumps are crankshaft driven triplex plunger pump. They are available in 3 categories:

Professional Use

Runs at RPM below 1000, mostly driven by pulley belt. (Direct drive with 6P/8P induction motor or inverter motor is also available). It works with PLC or advanced control system and sensors to build a complete logical system. It is recommended for industrial 24-7 operation. While working at low RPM, the wearable parts and lubricate oil endure longer and require less frequent maintenance.

Semi-professional Use

RPM runs between 1450 and 2000, mostly in direct drive (by 4P induction motor or low RPM engine). By combining with simple control panel or simple analogical control system, this category can be used for high pressure cleaning machine or basic high pressure system, ideal for low-intensity commercial use. Its low to medium working RPM consumes the wearable parts faster than professional use and requires more frequent oil change. The maintenance cost is therefore a bit higher than professional use.

DIY Home Use

Runs at RPM higher than 2500, mostly in direct drive (by 2P induction motor or high RPM engine). It is often operated by simple on/off switch and working with simple accessory. Guaranteed life cycle is less than 200 hours. It is recommended for home or less frequent use at less than 1 hour consecutive working condition.

Semi-professional Use

RPM runs between 1450 and 2000, mostly in direct drive (by 4P induction motor or low RPM engine). By combining with simple control panel or simple analogical control system, this category can be used for high pressure cleaning machine or basic high pressure system, ideal for low-intensity commercial use. Its low to medium working RPM consumes the wearable parts faster than professional use and requires more frequent oil change. The maintenance cost is therefore a bit higher than professional use.

DIY Home Use

Runs at RPM higher than 2500, mostly in direct drive (by 2P induction motor or high RPM engine). It is often operated by simple on/off switch and working with simple accessory. Guaranteed life cycle is less than 200 hours. It is recommended for home or less frequent use at less than 1 hour consecutive working condition.

Conmercial Hight Pressure Pumps

Our Direct-Drive High-Pressure Pumps are the ideal choice for a wide range of industrial applications, including cleaning, cooling, rust removal, and more. These pumps feature a direct-drive design, offering exceptional volumetric efficiency and reduced noise levels. This performance is achieved through our rigorous selection of precision components: specialized high-polymer engineering plastic high-pressure seals, wear-resistant rubber low-pressure seals, precision ceramic plungers, chrome-molybdenum alloy steel crankshafts, die-cast aluminum alloy bodies, and forged brass alloy cylinder heads. These components guarantee outstanding performance and an extended lifespan during operation.

Commercial Hot Water High Pressure Pump

Our Direct-Drive Hot Water High-Pressure Pumps deliver exceptional performance and reliability even under demanding conditions. They are specifically designed for high-temperature and high-pressure applications. All models are designed for a maximum inlet water temperature of 75°C and feature a direct-drive design, providing excellent volumetric efficiency and superior vapor pressure resistance.

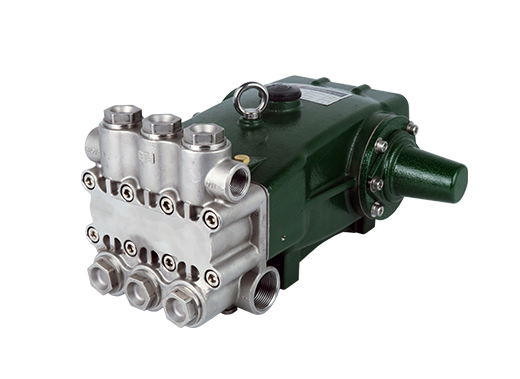

Industrial High Pressure Pump

Our Industrial High-Pressure Pump Series is engineered for demanding, continuous, high-intensity industrial applications. Whether you need cleaning, rust removal, surface preparation, pipeline pressure testing, or operation in other harsh environments, these pumps deliver consistent and reliable performance. All models feature a slow-speed design and are built with premium, high-quality components, including precision ceramic plungers, chrome-molybdenum alloy steel crankshafts, specialized high-polymer engineering plastic high-pressure seals, and wear-resistant rubber low-pressure seals. This ensures exceptional durability, lower noise levels, and superior volumetric efficiency.